Quality Printing: Your Brand’s Most Important Advocate

2024/10/16 2:58 pm

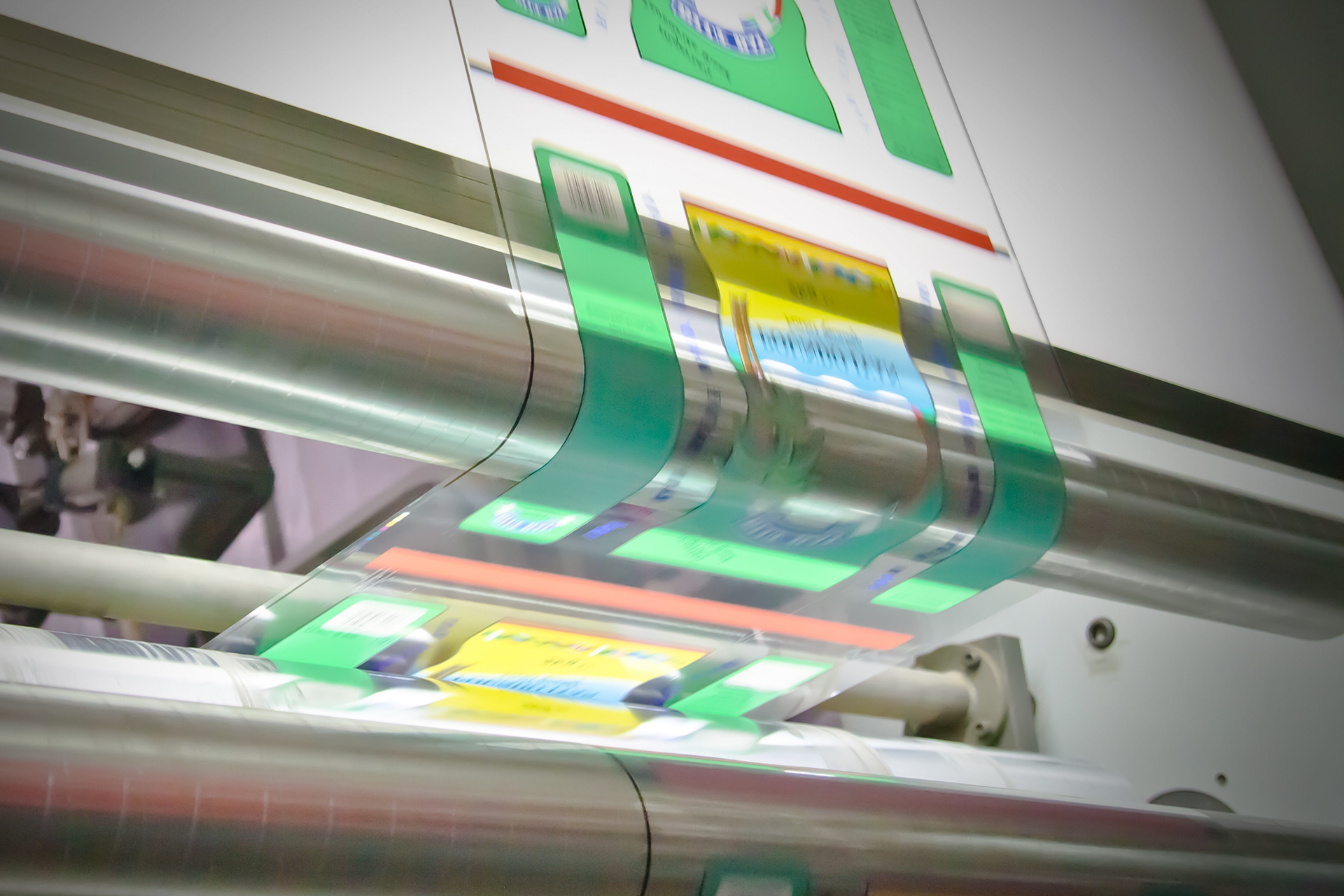

Packaging is the first point of interaction with your product, and nothing makes a stronger first impression than quality printing. But what separates poor printing from an exciting design?

Let’s explore critical printing considerations with strong packaging design examples.

Packaging Tips for Quality Print and Eye-Catching Designs

To start, it’s important to identify clear branding goals and develop your supporting artwork.

Include a White Back-Up Layer in Your Artwork

For clear bags and film, add a layer of white ink below your design to create print depth and sharpness. This prevents printing from looking opaque or see-through.

Overlap Adjacent Colors in Your Design

Prevent color separation during printing with trapping. Improper trapping will make print look sloppy and messy, and your supplier can help make sure your artwork is set up properly.

Process or Spot Printing? Your Branding Goals Will Decide

Packaging design and brand requirements determine the best printing style for your packaging. Both process and spot printing methods produce high-quality printing, but each works best for different packaging goals.

Process

Excels at creating more complex and realistic images. A combination of Cyan, Magenta, Yellow and Black dots are stacked to create any color.

Spot

Ideal for exact color matching for logos and brands that require it. A single PMS ink color is used for each color in your design.

Preserve Printing Quality with the Right Film

Quality printing starts before your films reach the printing press. Film treatments before printing help inks settle so your packaging makes it to the shelf in pristine condition.

| Tip You can test the quality of your film with a piece of clear tape! Place a piece of tape on your packaging. When you pull it off, did some of your printing come with it? If so, you should have a conversation with your supplier about how to improve your packaging’s print quality. |

Make Product Information Easy to Read

Consider how critical information and brand elements show up on your package.

Decide Between Light Text or Dark Text

Packaging readability depends on the background, font style and the total number of colors included.

Reverse Print

Lighter text on a dark background. Must be printed at a larger type size to avoid becoming blurred and illegible.

Positive Print

Dark text on a light background. Can be printed more clearly at smaller sizes than reverse print.

Emphasize Key Text and Logos with Drop Shadows

Drop shadows, done well, can draw consumer attention to priority text and your logo. Work with your supplier to avoid unintended color overlap in the printing process.

Determine UPC Code Placement

Place barcode on a white background and keep area around it clear to increase successful scans.

Follow Recommended Artwork Specifications

High-res artwork – created at 300 DPI – is a must for clear printing and imagery.

Choose a Supplier with the Right Capabilities

Once artwork is complete, your supplier can put its deep understanding of design and printing technologies to work.

Align Your Printing Needs with Supplier Expertise

State-of-the-art equipment is a good first indicator of expertise. Proven suppliers will also have the right processes in place to protect quality – from job start to finish.

Ask your supplier if they have the following technology and capabilities:

- Central impression press for greater printing precision

- Optical error detection to identify and resolve printing irregularities

- Exact color match capabilities

- Knowledge of process and spot printing

- Top-quality printing plates

Ensure Quality-First Operations are a Priority

Printing is just one part of the customer satisfaction equation. Make sure your supplier is putting quality first across its operations – from food-safety certified facilities to top-quality resins. Start your search by identifying suppliers with experience in your industry.

Why Great American Packaging

For nearly 60 years, we’ve honed our custom flexible packaging expertise for food, consumer packaged goods and natural products.

As part of our White Glove Service commitment to you, we promise:

- High-quality printing that stands out from the competition

- Lowest lead times in packaging industry

- Highest level of quality and consistency from your first bag to the last

- Food safety backed by IFS PACsecure certified facilities

- Recommend best packaging for your product, industry and retail space

- Full portfolio of sustainable packaging solutions

Reach out today to see how we can help you make a bigger impact on the shelf.

RECENT POSTS

- Quality Printing: Your Brand’s Most Important Advocate

- EPR PACKAGING LEGISLATION: IF YOU ARE A BRAND OWNER, YOU WILL BE AFFECTED

- WEBINAR | EPR LEGISLATION: WHAT BRAND OWNERS AND MANUFACTURERS NEED TO KNOW

- GREAT AMERICAN PACKAGING WELCOMES MARK MCANLIS AS VP OF SALES

- 5 Packaging Tips that Will Increase Your ROI